Precision mold machining refers to the manufacturing of high-precision molds for complex shaped parts through a specific process.The following is a typical process flow of precision mold machining:

1.Design and planning:First,based on the product requirements,the design engineer will develop the design drawings and specifications for the mold.This includes the size,shape,and material of the mold.At the same time,the feasibility of mold manufacturing and production costs need to be evaluated.

2.Material Selection and Procurement:According to the design requirements,choose the suitable material for the mold,usually the choice of high-speed steel,carbide,etc..Then,carry out the procurement of materials to ensure that the quality and specifications of the materials meet the requirements.

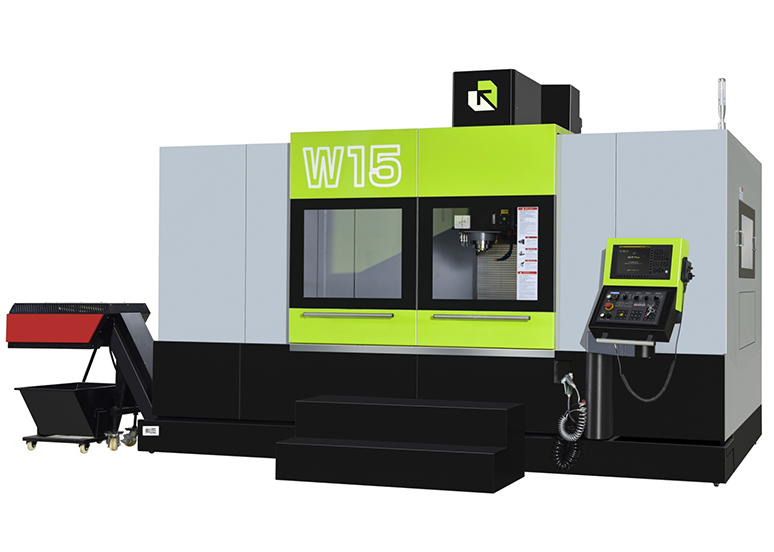

3.Processing preparation:Before processing,it is necessary to prepare a variety of processing tools and equipment,such as CNC machine tools,milling machines,lathes and so on.At the same time,it is also necessary to prepare auxiliary materials such as cutting fluid,lubricant and coolant.

4.Rough machining:According to the size and shape of the mold,use milling machine,lathe and other equipment for rough machining of the mold.This step is mainly to remove excess material and form the preliminary shape of the mold.

5.Heat treatment:After rough machining,the mold is heat treated to improve the hardness and wear resistance of the mold.Commonly used heat treatment methods include quenching and tempering.

6.Precision machining:Precision machining of the molds is carried out by high-precision equipment such as CNC machine tools.This step requires extreme precision and stability to ensure the accuracy of the shape and size of the mold.

7.Precision Grinding and Polishing:After precision machining,the mold needs to be meticulously ground and polished to improve the surface finish and geometry of the mold.

8.Assembly and debugging:the various parts of the mold are assembled,debugged and tested to ensure the normal operation and performance of the mold.

9.Inspection and quality control:Through various testing equipment and methods,the mold is inspected to ensure that the size,shape and quality of the mold meet the design requirements.

10.Delivery and Maintenance:After completing the quality inspection,the mold is delivered to the customer for use.At the same time,it is also necessary to carry out regular maintenance and repair,in order to extend the service life of the mold and keep good working condition.

The above is a rough process flow of precision mold processing.In practice,certain adjustments and improvements may be made according to specific mold types and requirements.At the same time,in order to improve processing efficiency and quality,automation and computer-aided processing technology can also be used.